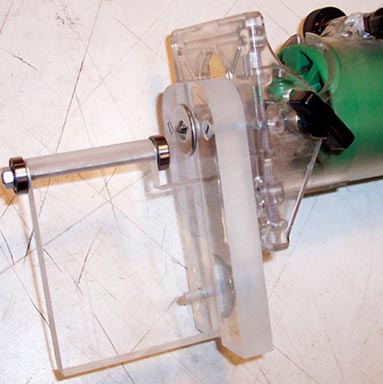

Arnt, someone else asked, but I too want to fully understand this tool you've made. I appreciate it's simplicity, but don't understand the adjustment in and out. I understand that the router has an adustment for depth.

What I'm wondering about is the width. Can you explain or offer another pic or two? TIA, Bruce

! I have enough for jigs and templates for years...

! I have enough for jigs and templates for years...